The linear oscillation of the laser beam is characterized by a sinusoidal operate whose extrema are situated in the sting areas of the melt pool and, as a result of low velocity, pulls the melt pool apart. Thus, a minimal irregular seam of roughly 10 mm starting at a defocusing of −1 mm and a laser beam position of −3.5 mm within the melt pool is achieved. These include pendulum amplitude, defocusing, and laser beam place of a disk laser with a wavelength at 1030 nm. In order for instance the effect of the laser beam on the melt pool, the processes are visually and thermally documented with a thermos digicam and 300 fps. The "laser assisted double wire welding with nontransferred arc" utilizes an arc burning between two laterally fed wires mixed with a laser beam supply and beam steerage. That's, the wires on every facet of the washer ought to be parallel to each other.

The linear oscillation of the laser beam is characterized by a sinusoidal operate whose extrema are situated in the sting areas of the melt pool and, as a result of low velocity, pulls the melt pool apart. Thus, a minimal irregular seam of roughly 10 mm starting at a defocusing of −1 mm and a laser beam position of −3.5 mm within the melt pool is achieved. These include pendulum amplitude, defocusing, and laser beam place of a disk laser with a wavelength at 1030 nm. In order for instance the effect of the laser beam on the melt pool, the processes are visually and thermally documented with a thermos digicam and 300 fps. The "laser assisted double wire welding with nontransferred arc" utilizes an arc burning between two laterally fed wires mixed with a laser beam supply and beam steerage. That's, the wires on every facet of the washer ought to be parallel to each other.

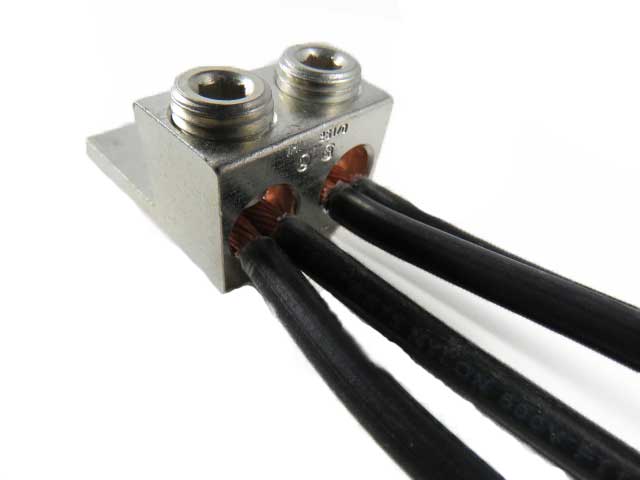

About 2″ from the block clamp the wires with the vise grips and the second washer such that a wire is on either side of the washer (above). The overall sort is connected by the left and right facet of the web, which is linked by straight string. Can choose two sorts of model, the widespread sort use spherical wire to make spiral mesh, can match the chain sort . In the process that follows you’ll want the following instruments: a bench prime vise, a couple of 7/8-1″ thick wood items, 1/16″ thick washers, 6″ of broomstick or 1″ diameter dowel and a kind of vise-grip pliers (discovered at most hardware shops) which has pivoting plates on the ends of the gripper arms. The protective zinc coating helps forestall rust formation, eliminating the necessity for regular painting or floor remedies. This makes galvanized steel extremely resistant to rust and corrosion, even in harsh environments or areas with excessive humidity. It is particularly suitable for installations in coastal or high-humidity areas where corrosion is a concern.

The steel wires used within the fence panels and framework are often galvanized or coated with a protective layer to boost corrosion resistance. The steel wires used within the fence panels and framework are sometimes galvanized or coated with a protecting layer to reinforce corrosion resistance. The steel wires used in the fence panels and framework provide a sturdy and strong structure that may withstand impacts and exterior forces. The steel wires used within the fence panels and framework present a sturdy and sturdy construction that can withstand impacts and exterior forces. PVC-Coated Wire: In addition to the primary structural supplies, the wires used in double wire fences will be coated with PVC (Polyvinyl Chloride) for added safety and aesthetics. PVC-Coated Wire: In addition to the first structural supplies, the wires utilized in double wire fences might be coated with PVC (Polyvinyl Chloride) for added safety and aesthetics. Galvanized steel is coated with a layer of zinc, which supplies glorious rust resistance, while coated steel may have additional protecting coatings reminiscent of PVC (Polyvinyl Chloride) or polyester. They are often coated or painted to prevent rust and corrosion. They are often coated or painted to stop rust and corrosion. Galvanized steel double wire fences have an extended lifespan compared to fences made from materials which can be more prone to rust and corrosion.

The steel wires used within the fence panels and framework are often galvanized or coated with a protective layer to boost corrosion resistance. The steel wires used within the fence panels and framework are sometimes galvanized or coated with a protecting layer to reinforce corrosion resistance. The steel wires used in the fence panels and framework provide a sturdy and strong structure that may withstand impacts and exterior forces. The steel wires used within the fence panels and framework present a sturdy and sturdy construction that can withstand impacts and exterior forces. PVC-Coated Wire: In addition to the primary structural supplies, the wires used in double wire fences will be coated with PVC (Polyvinyl Chloride) for added safety and aesthetics. PVC-Coated Wire: In addition to the first structural supplies, the wires utilized in double wire fences might be coated with PVC (Polyvinyl Chloride) for added safety and aesthetics. Galvanized steel is coated with a layer of zinc, which supplies glorious rust resistance, while coated steel may have additional protecting coatings reminiscent of PVC (Polyvinyl Chloride) or polyester. They are often coated or painted to prevent rust and corrosion. They are often coated or painted to stop rust and corrosion. Galvanized steel double wire fences have an extended lifespan compared to fences made from materials which can be more prone to rust and corrosion.

Corrosion Resistance: Galvanized steel is coated with a layer of zinc, which gives glorious corrosion resistance. PVC coating supplies resistance to corrosion, ultraviolet (UV) rays, and weathering. They offer glorious resistance to rust, staining, and corrosion, making them suitable for harsh environments. Double wire fences are usually constructed utilizing high-high quality supplies that offer energy, durability, and corrosion resistance. Using short lengths for wire leaders isn't a brand new concept. One concept behind using brief leaders for ono is that because the ono runs, the leader is next to the physique and thus less liable for cutoffs from different ono hanging the swivel or leader itself. The chief bent slightly because of the battle but no obvious damage was performed to either lure (since the ono inhaled it and the Japanese double hooks lodged in the gill rakers) or the chief. I have struggled with this for a while, going again and forth between wire cable and very heavy monofilament for ono (wahoo) fishing with predictable outcomes: many misplaced lures with mono and fewer hits with cable. Step one (above) is to make a gentle bend in the midst of the leader, then firmly clamp the wires in between a pair of wood blocks with about 2″ of wire loop sticking out.

댓글 달기 WYSIWYG 사용