Working with him, I sketched out the design for a shielded loop and the result was that seen in Figure 1. Since he was useful with a welder and had loads of pieces round it was a pure to make it out of scrap items of 1/2" electrical conduit and utilizing a conduit bender he fashioned a "sq. loop" that was about 18" (45cm) on a facet as proven in the picture. I calculated the required capacitance required to resonate the loop at 10.15 MHz using the calculator referred to above, and got down to create an inexpensive fastened-value capacitor with 4-5 KV breakdown voltage. To ensure that this to work nonetheless, there must be a gap in the shield or else it should merely "short out" the impinging magnetic field from the desired sign and for reasons mechanical, electrical and symmetrical, it is best that this gap be right in the midst of the loop. If there is a very egregious noise supply, it could also be possible to rotate the antenna to null it out - provided, in fact, that the noise supply is not in the same course as the specified signal!

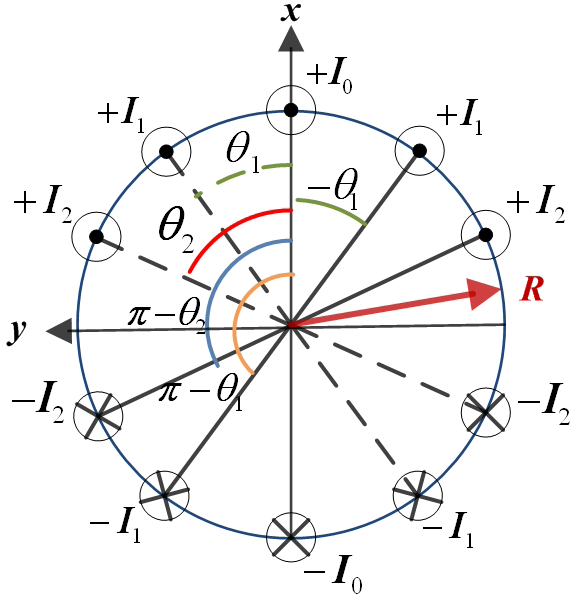

I did not need the antenna to be tunable since it is going to operate on a single spot frequency (10.149 MHz) permanently. This design is a single-frequency loop for 30-meter HF APRS operation (details here) which takes place on 10.149 MHz . The limiting factor on receive at 10 MHz is pure noise, not antenna efficiency. A loop antenna has a "figure 8" pattern and thus has two nulls and a level of directionality. At the bottom of the loop was welded a small plate of steel as could be seen near the left facet in the bottom picture of Figure 1. This plate was welded in the course of the loop, reverse the hole at the highest and such that when the plate was bolted to the facet of the utility field, it held the loop upright. Drill two holes holes through the diameter of the PVC pipe to support the small loop in the proper orientation.

I did not need the antenna to be tunable since it is going to operate on a single spot frequency (10.149 MHz) permanently. This design is a single-frequency loop for 30-meter HF APRS operation (details here) which takes place on 10.149 MHz . The limiting factor on receive at 10 MHz is pure noise, not antenna efficiency. A loop antenna has a "figure 8" pattern and thus has two nulls and a level of directionality. At the bottom of the loop was welded a small plate of steel as could be seen near the left facet in the bottom picture of Figure 1. This plate was welded in the course of the loop, reverse the hole at the highest and such that when the plate was bolted to the facet of the utility field, it held the loop upright. Drill two holes holes through the diameter of the PVC pipe to support the small loop in the proper orientation.

Click on small footage for bigger view in separate browser/tab. The photographs on this net page had been taken during this newer restore, after the unit had been in continuous service for 12-thirteen years. One (or more) loops to be placed near the indoor clocks to couple into them the now-amplified signal. This development creates a coaxial capacitor with the coax cable heart conductor being one plate and the INSIDE of the copper tubing being the opposite plate of a capacitor. The UBYTE-I Cable - a large Byte? But the worth is a moderately large Capacitance. This loop is then placed in order that it's about 1/2-inch (1.2 cm) away from the inside circumference of the big loop on the side opposite the open-ends & capacitor. The black blob on the left-hand facet of the Cable is a Anti-RFI Ferrite. I personally discover this Cable to be very natural sounding, with a nice tonal balance and glorious imaging and soundstaging.

In comparison to the X-1.5 the X-three sounds slightly too shiny, which can likely be offset in long runs by some natural rolloff. Below you possibly can see a X-three Cable in comparison to the X-1.5. Here a complete Turn (or twist) is persent only each three centimeters, roughly halving the contact-area between the two separate conductors and halving the Capacitance of the Cable to 100pF/m. It also makes use of only 1.2-1.3m Cable for every individual conductor and therefore has a lower Resistance. The X-1.5 Cable uses about 1.5-1.6m Wirewrap Wire for every of the 12 individual conductors. In cases like this the X-3.Zero is the higher Cable. This may simply not do for really lengthy Cables (just like the 5m I'll need in the future for the hyperlink from my Pre to my Mono-block Amp's (below improvement). It isn't very hygienical (don't tell folks that truly buy those Cables yeah?) however the only reliable stripper I've found are my teeth. Since I have written the last two Interconnect Articles I had each some feedback from you, the Readers and have made a couple of more Cables myself. I'm measuring the Cables Capacitance. The X-1.5 Cable has about 200pF Capacitance per meter and a loop-resistance of about 0.2 Ohm per Meter.

댓글 달기 WYSIWYG 사용